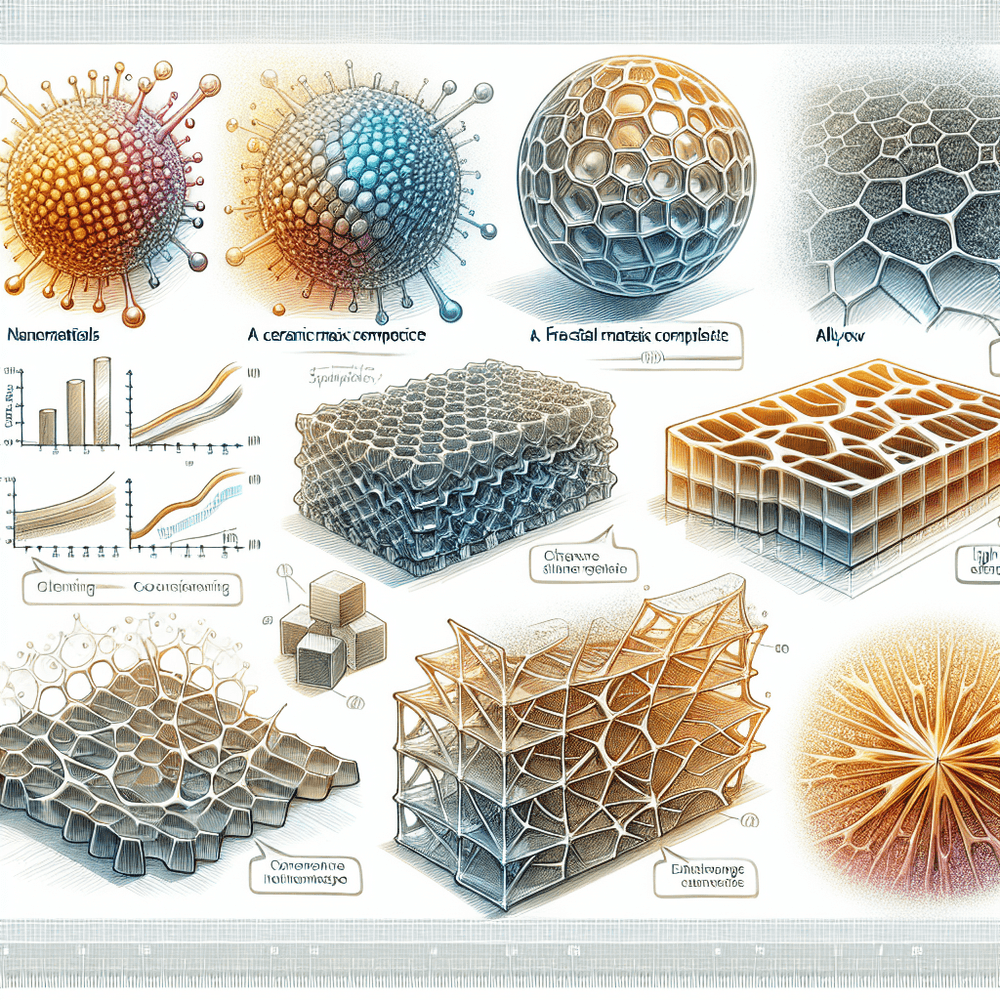

Examples of Innovation in Material Science

Last updated on 2024-12-20

Material science is evolving rapidly, driven by the demand for advanced materials that can meet the needs of emerging technologies. As industries increasingly focus on sustainability, there is a significant shift toward developing materials that are not only efficient but also environmentally friendly. The rise of nanotechnology, biomaterials, and 3D printing is reshaping the landscape, enabling the creation of lighter, stronger, and more versatile materials that can be tailored for specific applications. This evolution is further influenced by the push for circular economy principles, which emphasize recycling and reusing materials to minimize waste.

External trends, such as the increasing emphasis on renewable energy and electric vehicles, are also shaping the future of material science. Researchers are exploring new materials that can enhance energy storage and conversion, addressing the challenges associated with battery performance and longevity. Additionally, the integration of artificial intelligence and machine learning in material design is accelerating the discovery of new compounds and optimizing manufacturing processes. As the field continues to advance, collaboration across disciplines and industries will be essential to unlocking the potential of materials to meet the complex challenges of modern society.

1. Graphene

Graphene is a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice. It exhibits extraordinary mechanical, electrical, and thermal properties, making it a highly sought-after material in various applications. Researchers continue to explore its potential in electronics, composites, and even biomedical devices.

Examples of Products and Services

Graphene batteries

Graphene batteries are advanced energy storage systems that utilize graphene materials to enhance performance in various applications, including electric vehicles and consumer electronics. These batteries are characterized by their lightweight design, durability, and ability to significantly reduce charging times. They often incorporate innovative components, such as sulphur cathodes and dendrite-free lithium anodes, which contribute to higher capacity and longer life cycles, potentially exceeding 2000 charge cycles. With a high surface area for ion storage, graphene batteries promise increased energy density, making them a compelling option for future energy solutions.

Graphene coatings

Adam's UV Graphene Ceramic Coating is a nanocrystalline surface treatment designed to protect vehicles from environmental factors such as weather, chemicals, and UV rays. This coating features graphene technology, which enhances durability and water-repellent properties, allowing for improved resistance to dust and water spots compared to traditional ceramic coatings. It offers long-lasting protection, with a lifespan that can exceed six months, though application may require more skill due to its robust nature. Suitable for various vehicles, including cars, motorcycles, and boats, this product aims to maintain surface integrity and appearance over time.

Graphene sensors

The product is a range of hypersensitive sensors utilizing graphene as the primary material. These sensors are designed for various applications in biosensing, diagnostics, and environmental monitoring, leveraging graphene's large surface area to enhance sensitivity and detection capabilities. They can measure a variety of parameters including force, deflection, curvature, and the presence of hazardous particles or pollutants. The technology includes configurations suitable for microelectromechanical systems (MEMS) and offers improved performance in magnetic field measurements, making it applicable in diverse fields such as biomedicine and environmental science.

2. Biodegradable Plastics

Biodegradable plastics are designed to break down more quickly than traditional plastics, reducing environmental impact. Advances in material science have led to the development of new polymers that can decompose naturally, making them suitable for a variety of applications from packaging to disposable products.

Examples of Products and Services

PLA (Polylactic Acid)

Polylactic acid (PLA) is a biodegradable thermoplastic polyester derived from renewable resources such as corn starch and sugar cane. It is widely recognized for its biocompatibility and safe degradation, as it breaks down into lactic acid, a substance naturally produced by the body. PLA is easy to process and has desirable mechanical properties, making it suitable for various applications, including medical implants like stents and drug delivery systems. Its versatility also extends to uses in 3D and 4D printing, where it serves as a compelling material choice due to its sustainable origins and effectiveness.

PHA (Polyhydroxyalkanoates)

Polyhydroxyalkanoates (PHAs) are a group of natural biodegradable polyesters produced by various microorganisms through the fermentation of sugars or lipids. These biopolymers exhibit properties such as biocompatibility and biodegradability, making them suitable alternatives to traditional non-degradable plastics for short-term applications. PHAs can be synthesized using a variety of feedstocks, including vegetable oils, sugars, and even waste materials, allowing for a sustainable production process. Their versatility in structure and function enables tailored applications across multiple industries, promoting eco-friendly practices.

Starch-based plastics

Starch-based plastics are biodegradable materials created by blending natural starch with various compostable polymers such as PLA, PBAT, and PBS. These bioplastics aim to reduce reliance on petroleum-based products by utilizing renewable resources, thereby lowering carbon footprints. While offering properties comparable to traditional packaging materials, they face challenges in home compostability and large-scale production. The market for starch-based plastics is growing, with significant projected increases in value, reflecting a rising interest in sustainable alternatives for packaging and other applications.

Related Innovations in Other Fields

3. Self-Healing Materials

Self-healing materials are capable of automatically repairing themselves after being damaged. This innovation has the potential to significantly extend the lifespan of products and reduce waste. These materials often incorporate microcapsules or vascular networks that release healing agents when a crack or break occurs.

Examples of Products and Services

Self-healing polymers

Self-healing polymers (SHPs) are a class of synthetic materials designed to autonomously repair physical damage without human intervention. These materials can recover from mechanical injuries such as cracks and delamination, utilizing mechanisms inspired by natural processes. SHPs exhibit both mechanical and electrical healing capabilities, making them suitable for various applications in industries such as construction, automotive, and electronics. Recent advancements focus on the preparation and structure-property relationships of these polymers, enhancing their effectiveness and potential for commercial use.

Self-healing concrete

Self-healing concrete, often referred to as bio-concrete, is a specialized type of concrete engineered to autonomously repair cracks as they occur. This material incorporates specific bacteria, such as Bacillus pasteurii, along with nutrients that allow the bacteria to thrive and produce calcium carbonate when cracks form, effectively sealing them. Additionally, some formulations utilize polymers to enhance flexibility and facilitate quicker healing within 24 hours. This technology minimizes the need for regular maintenance and repairs, addressing concerns related to corrosion and extending the lifespan of concrete structures.

Self-repairing coatings

The product is a self-healing coating designed for various applications, including automotive and industrial uses. This coating utilizes a physical self-healing mechanism that allows it to close gaps and seal cracks, enhancing durability and longevity compared to traditional coatings. It is formulated with ceramic polymer chains that provide robust protection and resilience, making it effective against damage such as scratches and wear. The self-healing properties are particularly beneficial in environments prone to abrasion or environmental exposure, as they help maintain the integrity and appearance of the coated surface over time.

4. Aerogels

Aerogels are ultra-lightweight materials derived from gel, in which the liquid component is replaced with gas. They possess exceptional thermal insulation properties and are considered one of the lightest solid materials known. Their applications range from insulation in buildings to space exploration.

Examples of Products and Services

Silica aerogel

Silica aerogel is a highly porous, nanostructured material known for its low density and exceptional insulating properties. Made by removing the liquid from silica gel while preserving its structure, it maintains a significant portion of its original volume. The material is often described as feeling like fragile styrofoam and has been utilized in various applications, including as insulation for NASA's Mars rovers. Silica aerogel exhibits a high specific surface area and low dielectric constant, making it suitable for diverse industrial and scientific uses.

Carbon aerogel

Carbon aerogel is a lightweight, porous material primarily composed of carbon nanoparticles, recognized for its unique properties such as high surface area and electrical conductivity. It is produced through a process that involves the pyrolysis of organic aerogels, resulting in a material suitable for various applications, including energy storage and conversion. Carbon aerogels can be utilized as electrode materials due to their renewable and cost-effective nature, making them an attractive option for enhancing energy density in battery technologies. Additionally, advancements in 3D printing techniques are being explored to scale up the production of carbon aerogels, further broadening their potential applications.

Polymer aerogel

The product is a highly porous polymer aerogel designed for various engineering applications, combining mechanical robustness with lightweight properties. This aerogel is noted for being three times denser than typical aerogels while offering over 100 times the strength. It features unique properties such as superlipophilicity and hydrophobicity, making it suitable for diverse uses, including energy generation through triboelectric nanogenerators. The material is developed using advanced polymer chemistry techniques, enabling significant performance enhancements without the need for additives.

5. Smart Textiles

Smart textiles are fabrics that have been engineered to possess functionalities beyond traditional uses. This includes the ability to monitor health metrics, change color, or even respond to environmental stimuli. The integration of sensors and conductive materials into textiles is transforming the fashion and healthcare industries.

Examples of Products and Services

Wearable health monitors

The product is a range of wearable health monitoring devices that are designed to continuously track and record various vital signs, such as heart rate, blood pressure, and glucose levels. These devices, which include microfluidic patches and wearable ECG monitors, are utilized for both personal health management and clinical research. They provide users with real-time data on their physiological status, enhancing the ability to monitor health conditions and potentially assist in diagnosis. Medical-grade versions of these wearables undergo rigorous clinical testing to ensure their accuracy and reliability.

Color-changing fabrics

The product is a color-changing fabric that utilizes thermochromic technology, allowing it to alter its hue in response to temperature changes. This fabric can be used in various applications such as garments, curtains, and tablecloths, making it suitable for both DIY projects and commercial uses. It incorporates a conductive micro-wire that activates color changes when an electrical current is applied, enabling programmable color shifts through simple gestures. This technology mimics natural camouflage abilities found in animals, like zebrafish, and can incorporate different techniques, including photonic crystal fibers and liquid crystal inks, to achieve its dynamic color-changing properties.

Thermal regulating textiles

The product is a temperature-regulating textile designed for apparel, which incorporates advanced materials such as boron nitride and carbon nanotubes. This textile actively responds to changes in body heat, effectively managing thermal insulation and moisture transfer to enhance user comfort. By trapping air and utilizing smart polymers, it reduces heat peaks and minimizes sweat formation, making it particularly suitable for athletes and individuals seeking optimal thermal management in various conditions.